Business

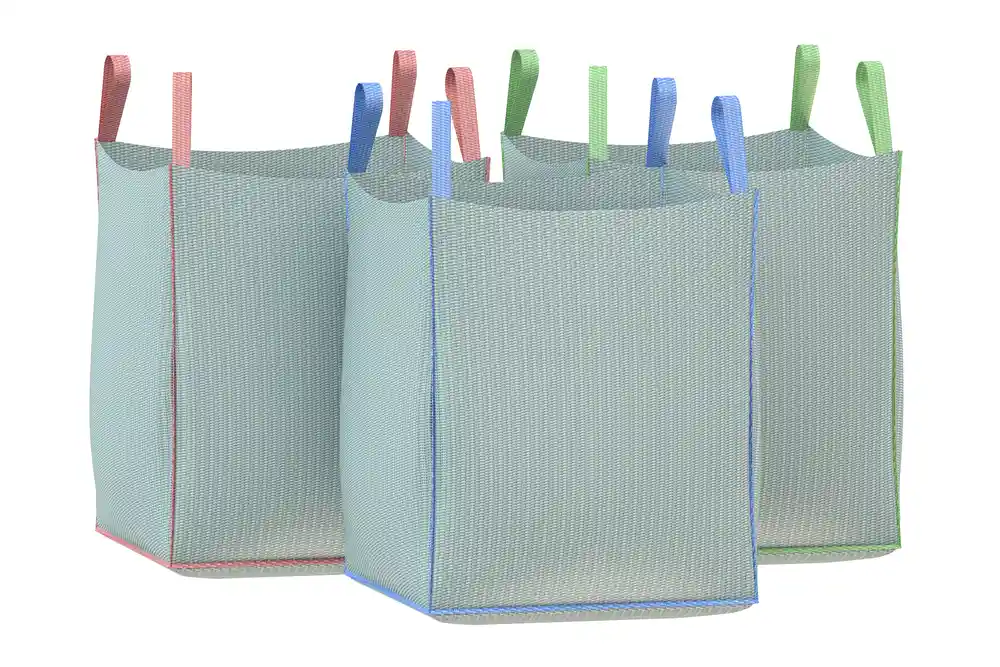

Get The Best Quality FIBC Bags From Custom Processing and Packaging Products

How do you get the Best Quality FIBC Bags from Custom Processing and Packaging Products? The first is to find a reputable FIBC bag supplier. These can range from local businesses to a huge corporations and can even be an overseas manufacturer. Once you’ve chosen a reputable FIBC supplier, you should scrutinize them for red flags and do your homework.

FIBC Bulk Bags

FIBC bags that are fitted with form-fit liners are an excellent option for bulk storage. These bags are made of similar materials to tube liners and are custom-made to fit FIBCs precisely. Because the liners are designed to fit in the exact same way, they reduce the chances of bunching or contamination and allow the product to flow to the top and corners of the bag. These bags also have matching discharge and fill spouts, preventing the product from spilling out of the FIBC. And because they are taller than tube liners, you can stack multiple bags.

They come in flat, lay flat, baffled, and form-fit configurations. They are oxygen, moisture, puncture, and odor-resistant. For liquid products, foil liners reduce product odor. These liners are also form-fit to FIBCs, which enhances handling and filling processes.

Buy FIBC Bags From Custome Packaging Products

FIBC bags are manufactured from virgin polypropylene resin to minimize the risk of contamination. In addition to this, they should be made in BRC-certified facilities to ensure adherence to the highest standards. Additionally, these bags should be manufactured under hygienic conditions and must have a metal detection facility. Finally, they should be produced under stringent record-keeping procedures. Regardless of the product, you need to store, Custom Packaging Products is here to help.

In addition to offering superior quality and exceptional customer service, FIBC bulk bags also conducts strict hygiene and quality checks, hazard analysis, and critical control points to ensure the safety of the products stored in their FIBCs. In addition to these, food-grade FIBC bags from Custom Packaging Products meet strict international standards to protect products. They are also eco-friendly and meet food safety standards. When looking for the right FIBC bags, it is important to consider their GSM and safety factors.

FIBCs are filled via a sized inlet spout or open top. Various filling processes are available, from manual to fully automated multistage systems. FIBC emptying processes are similar to those of filling processes, ranging from simple manual operations to automated systems. Custom Packaging Products’ experts can help you determine the right FIBCs for your specific application.

If you are considering using FIBCs to package your feed, you may be interested in a variety of configurations. Some are U Panel, while others may be circular. Each of these bulk bags has its own unique construction, which may not include a liner. Most bulk bags are categorized by their construction and intended application. U Panel bulk bags, for example, must have 2 seams on opposite sides.

The Bottom Lines

For producers of starch, the bulk density of the product is an important consideration. While some products may stack easily and neatly using the pyramid-stacking technique, others may not. The type of liner used will have a bearing on the environment of the filled bulk bag. Some types of liners are hermetically sealed, while others do not. Choosing the right FIBC bag for your feed is crucial for the long-term health of your feed business.

Details news here https://www.dailysmallnews.com

Related posts:

Categories

- Apps (1)

- Automotive (23)

- Beauty (7)

- Business (117)

- Celebrities (2)

- Digital Marketing (21)

- Ecommerce (1)

- Education (18)

- Entertainment (25)

- Events (6)

- Features (4)

- Fitness (10)

- Food (1)

- Forex & Crypto (15)

- General (105)

- Health (48)

- House (61)

- Lifestyle (48)

- Marketing (8)

- Parenting (3)

- Pets (10)

- Real Estate (7)

- Safety and Security (11)

- Social Media (20)

- Sports (96)

- Technology (67)

- Travel (22)